Processing and Technology

We focus on processing materials which are difficult to process: dense, gellike polymeric and colloidal materials with viscoplastic behaviour and materials with internal interfaces, researching what happens in and at interfaces.

Novel processing methods

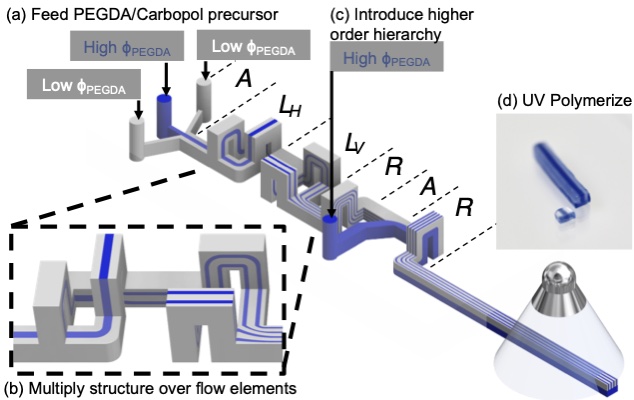

We study the use of special static mixers, which advect disparate streams through serpentine splitting, rotation, and recombination elements.These elements can be used to multiply the incoming 2D concentration field across the cross-sectional area while preserving its relative spacing and orientation. They can be combined with additive manufacturing methods such as 3D printing. We have also used these approaches to produce monodisperse emulsions from high viscosity ratio constituents. In the first stage, a custom static mixer generates co-flowing layers of alternate phases, and progressively thins layers until they rupture, thus forming a high-internal phase emulsion. Finally we have been exploring such approaches to structure meat replacement products, which are protein gels.

Selected references

- Bayles, A. V., Pleij, T., Hofmann, M., Hauf, F., Tervoort, T., & Vermant, J. (2022). Structuring Hydrogel Cross-Link Density Using Hierarchical Filament 3D Printing. ACS Applied Materials & Interfaces, 14(13), 15667-15677.

- Hofmann, M., Bayles, A. V., & Vermant, J. (2021). Stretch, fold, and break: Intensification of emulsification of high viscosity ratio systems by fractal mixers. AIChE Journal, 67(5), e17192.

- Schaller, R., Hoffmann, M., Bayles, A. V., van Hooghten, R., Meijer, H., Tervoort, T., & Vermant, J. (2020). Efficient processing pathways to create high interface materials. In Bijels (pp. 193-210).

Fundamentals for processing high interface or gel-like materials

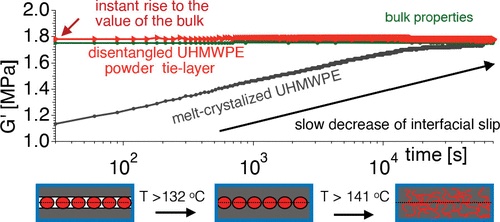

We study the fundamentals of processing multiphase and gel-like materials, e.g. by looking at the stability of multiphase flows or studying the microscopic phenomena at interfaces. One prime example is the use of ultra-high molecular weight polyethylene (UHMWPE), which is a high-end engineering polymer. However, the very features that lead to its exceptional properties, i.e., ultra-long macromolecular chains, render joining two surfaces of this material a tedious and slow process, leading to long welding times and impeding mechanical recycling of UHMWPE.We discovered the anomalous fast joining of UHMWPE interfaces by simply depositing small amounts of nascent disentangled UHMWPE powder at the interface, which provides a direct indication of the entropy-driven “chain explosion” upon melting of nascent disentangled UHMWPE.

selected references

- Christakopoulos, F., Troisi, E., Friederichs, N., Vermant, J., & Tervoort, T. A. (2021). “Tying the knot”: Enhanced recycling through ultrafast entangling across ultrahigh molecular weight polyethylene interfaces. Macromolecules, 54(20), 9452-9460.

- Christakopoulos, F., Troisi, E., & Tervoort, T. A. (2020). Melting kinetics of nascent poly (tetrafluoroethylene) powder. Polymers, 12(4), 791.

- Brem, A., Lhost, O., & Tervoort, T. A. (2020). Influence of solvent quality and crystallization conditions on the drawability of ultra-high molecular weight polyethylene cast from solution. Macromolecules, 53(14), 5957-5970.

Applications

Application domains are again quite broad, but are mainly focused on additive manufacturing. For example, applying the advective assembly techniques in 3D printing of actuators (external page SFA Manufhaptics), or the printing of liquid crystalline polymers (with the complex group at ETH). Yet also pursue the potential of the insights gained above in the recycling of high-end polymeric materials or in more sustainable multiayered materials for packing.

Selected references

- Gantenbein, S., Masania, K., Woigk, W., Sesseg, J. P., Tervoort, T. A., & Studart, A. R. (2018). Three-dimensional printing of hierarchical liquid-crystal-polymer structures. Nature, 561(7722), 226-230.

- Ghazaryan, G., Hausmann, K., & Tervoort, T. A. (2020). Influence of solid‐state biaxial orientation on the adhesion between poly (ethylene terephthalate)/tie layer/isotactic polypropylene multilayer films. Journal of Polymer Science, 58(3), 446-454.